This article was featured in the 2025 Northeast Sustainable Energy Association (NESEA) BuildingEnergy Magazine

By: John Hyde, Director of Sustainability at Chapman Construction/Design

Introduction

Over the past few decades, the design and construction industries have focused heavily on improving the performance of our buildings and reducing operational energy, and they have been very successful at doing so, especially here in New England and on the West Coast. Our buildings are more durable, use less energy, emit fewer carbon emissions, have better indoor air quality, and are more comfortable to live and work in. The building codes in Massachusetts are now updated by the Department of Energy Resources (DOER), and they prioritize energy efficiency and include aggressive performance pathways for new buildings, like meeting Passive House standards. Some of the largest and most efficient fully electric buildings in the world are located right here in Boston. Building one is simple if you have the financial resources: design an airtight, well-insulated enclosure, minimize thermal bridging, install a fully electric heat pump system with energy recovery and ventilation, and power the building with clean, renewable energy. The industry has been so focused on designing and building new high-performance net-zero energy buildings, it is now becoming the norm.

Eliminating or dramatically reducing operational carbon emissions from our buildings is great for our local air quality and reduces the impact of our buildings on global warming. Our success in building high-performance, low-energy buildings cannot be understated. This change is significant, as it plays a large part in moving towards meeting our ambitious goal of reaching net-zero carbon emissions by 2050. However, just reducing operational carbon emissions is not a complete solution. To survive this climate crisis, we need to continue reducing operational carbon emissions while broadening our focus to include the reduction of embodied carbon emissions, too. And the time to do so is not. We need to shift our attention and praise away from shiny new buildings and redirect it toward our existing building stock.

Broadening Our Focus: Embodied Carbon and Building Reuse

The building industry contributes significantly to climate change, accounting for 39% of global emissions. Embodied and operational carbon emissions are difficult to conceptualize, as they refer to the greenhouse gas emissions associated with the entire life cycle of a building, including emissions from extraction and manufacturing, transportation, construction, operation, and disposal. One of the most impactful ways to reduce embodied carbon emissions is to reuse existing structures instead of building new ones. By reusing an existing structure, we use fewer new building materials and thus avoid the emissions associated with their production, installation, and disposal. The environmental benefits of reusing existing buildings cannot be overstated—studies have shown embodied carbon can be reduced by 60-80% compared to building new. In addition to the environmental benefits, reusing existing buildings will generally cost less, reduce construction duration, and preserve the historical character of neighborhoods.

Existing buildings can be adapted for new uses, such as converting an old factory into residences, offices, or schools. They can be retrofitted with air sealing, insulation, windows, and roofing to improve their performance. Mechanical systems can be modernized to include electric heat pump systems with energy recovery and continuous ventilation. With thoughtful planning and creativity, existing buildings can become part of our strategy for addressing climate change while delivering the added benefits of reduced operating costs, improved indoor air quality, greater comfort, and lower embodied carbon emissions.

Demolishing a building creates a significant amount of waste, and the materials are often sent to a landfill. Despite our best intentions and efforts over the past few decades, the industry has not made significant progress in construction and demolition waste diversion and recycling. Beyond metal, concrete, clean drywall, and wood, most debris is either burned to produce energy or sent to a landfill. Often, these materials are in good and serviceable condition, but instead of being salvaged and reused, these resources are disposed of. Deconstructing and salvaging takes additional time, is more logistically challenging, and is more expensive than demolishing and sending to a waste processing facility. Deconstruction and salvage markets are promising, but until they are more developed and available at large scale, most of our construction and demolition debris will continue to end up in a landfill.

Overview: The Element Care Project

In 2020, Element Care of Lynn, Massachusetts, was in search of a new building for their headquarters and PACE Center. They were given the opportunity to take possession of a portion of the Union Hospital Campus, which was scheduled for demolition.

Exterior of project site, showing original structure

The 25,000 sf building was built in the 1950s, had solid bones, and no leaking through below grade foundation walls, but its systems and finishes were in disrepair and beyond their useful life. Element Care decided to reuse and repurpose the building, converting it to office space and a PACE (Program of All-Inclusive Care) Center for the elderly population in Lynn. The team decided that the best path forward was to keep the structure and exterior cladding, selectively demolish other systems, and perform deep energy retrofit.

Obstacles: Construction Was Not Without Its Challenges

The structure of the building was in great shape but was slightly undersized for Element Care’s needs. The original building was 25,000 sf, which provided them with just enough square footage for their needs and dramatically improved circulation. Reusing an existing building is not without challenges; here are some obstacles we overcame for a successful outcome:

- The building required new domestic water, fire water, electrical and stormwater management systems. Bringing in the new primary electrical service required us to core drill through an existing shallow and active 48″ culvert just a few feet from the building which could not be relocated. We secured a variance from the utility provider and all electrical is to run the concrete duct bank over the culvert and protect it with steel plating.

- Although the existing elevator shaft was wide enough and had sufficient overhead clearance in a new elevator cab, it was 4″ too shallow. We were able to selectively demo 6″ of concrete from the top of the slab, and then add a high strength topping slab to meet the elevator manufacturer’s height requirements.

- The existing slab was not insulated and had no vapor barrier. The slab required extensive saw-cutting, and we removed approximately 35% of the slab to install new underground plumbing and electrical utilities. Once the slab was patched back in, we installed a typical moisture mitigation system to control vapor movement through the slab.

- The existing stairways were cast in place concrete and did not meet current code requirements. We modified the treads and risers, then installed new railings to make the stairways code compliant.

- The brick veneer was separating from the building in dozens of locations. Fortunately, the brick and bed joint showed no signs of degradation. We were able to restore the masonry by repointing, flashing joints, rebuilding cracked piers, and using helical ties to secure veneer where the brick ties had corroded and failed.

- The percentage of original openings was over 50%, great for reducing energy demands but not code compliant for egress. We modified and increased the size of some window openings to bring in natural light and visually connect the building occupants to nature.

- The CMU waterproofing coating contained asbestos which added an additional step to creating new and larger window openings. We had to safely remove the brick, then abate the coating, and then finally demo the CMU to create the new opening.

- The building enclosure system was upgraded and included passive house design standards. We air sealed the building, carefully addressing thermal bridging at the foundation, walls, and all openings in the slab, walls, and roof. We minimized thermal bridging, the walls were insulated from the inside and included continuous insulation over the CMU and cavity insulation between framing. The roof received continuous insulation and membrane. Use of spray foam was limited, it was used sparingly between the top of walls and roof to air seal and insulate rough-to-rough framing.

- The HVAC system is entirely new and consists of a highly efficient, fully electric VRF heat pump system with energy recovery, fresh air ventilation, and a dehumidification system. All the HVAC equipment was fully commissioned, and the ductwork air leakage tested to confirm the system was performing optimally.

Interior hallway of project site, showing existing conditions

Rear exterior of project site, showing original structure

Defining Success: People, Profit, and Results

Despite these obstacles, reusing the building presented significant benefits to people, profit, and planet.

People: The local community now has access to essential medical care and support services, regardless of their financial situation. We preserved the building, maintaining the historical significance of the former Union Hospital and city benefactors.

Profit: Chapman Construction had a cost plus a fee agreement for the project. We made a fair profit, while saving Element Care more than $1.3M million.

Planet: By reusing the existing concrete structure, we avoided emissions from demolishing the building, trucking the debris offsite, preparing the site for the new structure, and the emissions for new concrete, structural steel, and metal decking.

Results: We avoided emitting over 630 MTCO2 e. It would take 61 acres of mature forest to absorb this amount of CO2 in a year.

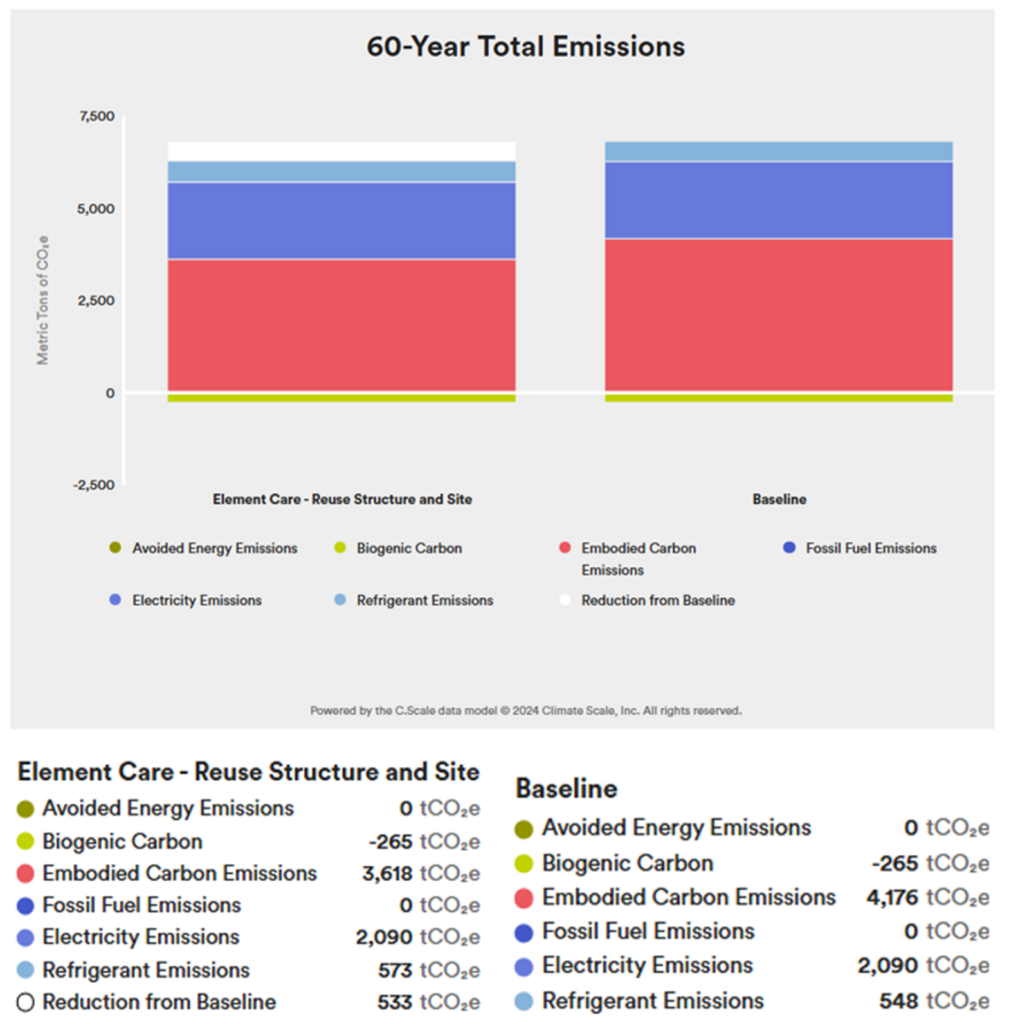

Embodied carbon comparison of demolishing the existing building and new structure versus reusing existing building and 80% of brick cladding. Image credit: C.Scale

Kay Takeaways: Lessons Learned & Opportunities

Our A5 phase emissions from construction activity were higher than they ought to have been. The project spanned the cold winter months, and the building was leaner than it could have been during construction. As a result, we burned a total of 3,801 therms of natural gas to temporarily heat the building, emitting 202 MTCO2 e. In the future, we’ll look more closely at options to minimize temp conditioning during construction or, as possible, incorporating automatic temperature controls, and including more time to temporarily light the building.

We’d also investigate the use of electric-powered equipment, for activities such as saw cutting, concrete, excavating, compacting soils, and finishing concrete, we’d specify the use of electric and battery-powered equipment, capable of demoing and excavating on the interior of a building. If available, we’d purchase renewable energy to power the equipment. Instead of using 30a-powered generators for corded tools, we’d use battery storage systems that are much more efficient.

We cut out a significant portion of the slab on grade to accommodate underground plumbing and electrical. Instead of using regular concrete, we could have used low embodied-carbon ready mix and saved 20% of our embodied carbon emissions from concrete.

Managing a Successful Building Reuse Project

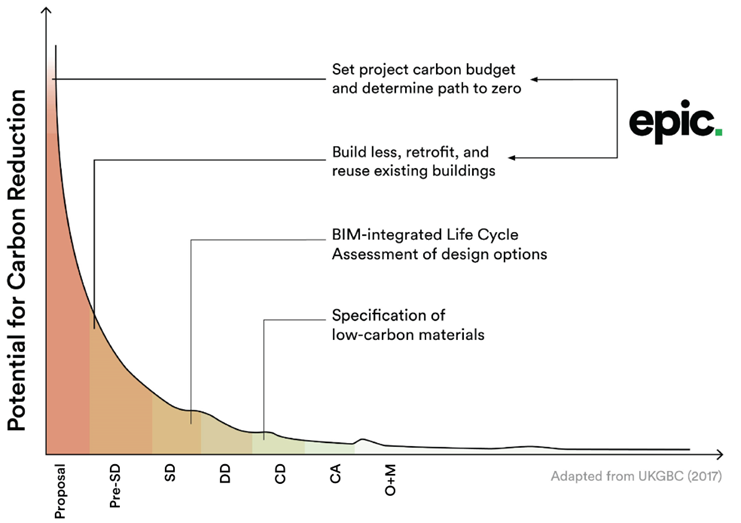

Establishing sustainability and carbon reduction goals at project inception is one of the most important decisions you’ll make. Once identified, your sustainability goals become project goals, an integral part of the project and not considered an add-on that is easily stripped away when challenges arise.

Deciding to reuse an existing building versus building new is one of the most impactful decisions you can make to reduce carbon emissions. When getting involved with a project, ask yourself this: “What actionable measure can I take to reduce the environmental impact of this project?” Don’t assume that building new is the only option and that reusing an existing building has already been funded and can be built at all times. You may need to start and be prepared to pose the question, “Is a new building really required?” How would it suit my existing needs in a cost the client’s needs?”

It’s important to perform a comprehensive building conditions assessment when deciding whether to reuse an existing building or tear it down and build a new one. At a minimum, evaluate the site conditions, utilities, structure, enclosure system, mechanical systems, and electrical systems. With this information, you can properly compare the cost and environmental impact of reusing existing or building new.

Asking these questions may not be easy, especially when your fee arrangement is a percentage based on a cost, as you’ll likely make less profit on a project and work harder. At Chapman, we often focus on the planet rather than on profit. While profits are important, however, they are not equally weighted. We work to calculate our short-sighted thinking about costs and do what is right for the planet.

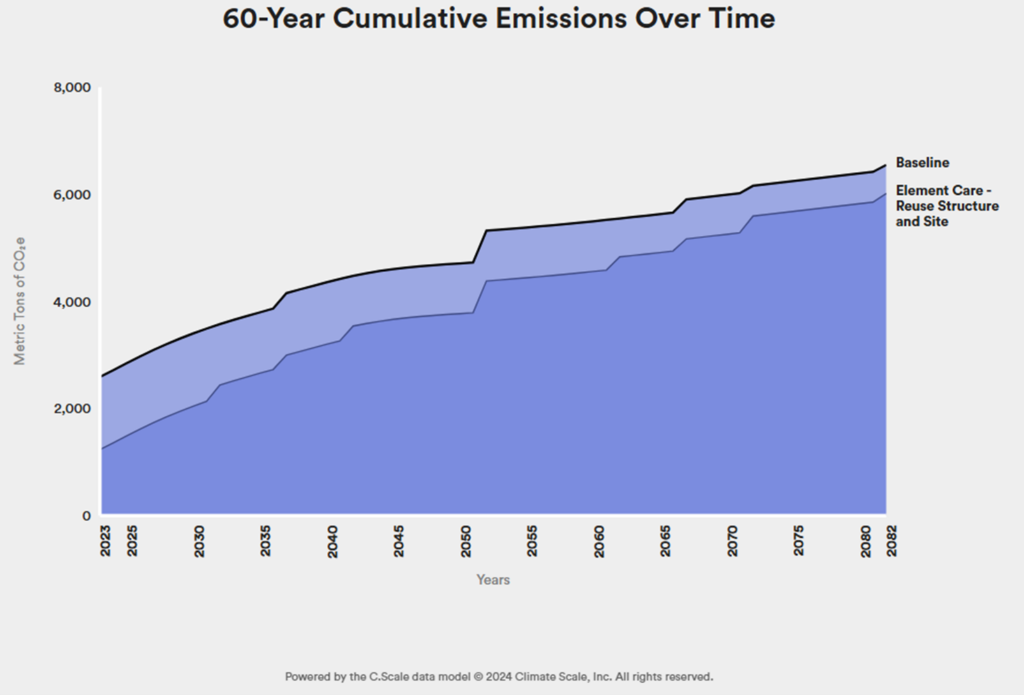

Cumulative emissions of assumed 60 year life of building. Image credit: C.Scale

Image credit: C.Scale

It’s Time to Get to Work

Focusing on embodied carbon is urgent, but there is a time value of carbon that is important to consider. Reusing existing buildings is a powerful tool, and it’s affording ourselves the opportunity to avert those emissions, work on long-term solutions, and learn how to adapt to a changing climate. Delaying carbon emissions for a longer period is of more value. If you want your project to have a positive impact on the community, your client’s bottom line, and the environment, choose to delay carbon emissions and renovate an existing building.

We are living in real time through a climate crisis, one that we are unfortunately too late to solve. The good news is that we can take action to help us survive it. Reusing existing buildings is an incredible tool to have in our arsenal. Change happens when the market thinks it is scalable to let’s use it! Celebrate reuse of existing buildings. Appreciate the cars and imperfections. When design professionals and builders align their efforts towards a common goal, such as building with purpose, truly meaningful change can occur.

Sources: gbc/d, ARUP — The time Value of Carbon Report CSA Group — Exploring Circular Strategies to Extend the Life of Existing Buildings